The complete guide to capacity management

How familiar are you with the terms supply and demand? Even if you're not an economics major, you've likely heard them before.

Supply and demand play a vital role in capacity management, but these two terms are just one piece of the puzzle.

It takes a lot more to understand how to effectively manage capacity and why that's important for projects' and companies' success.

In this guide, we'll shed light on capacity management:

- Its definition and examples,

- The process of managing capacity,

- Capacity management importance,

- The challenges that may occur when managing capacity, and

- Capacity management strategies you can follow to overcome the most common issues.

What is capacity management? (+ important capacity terms)

Capacity management is the process of ensuring that companies maximize their production output. With proper capacity management, businesses can keep an eye on how much they can achieve, produce, or sell within a particular period.

Before we go into further details about what capacity management entails, let's first define some of the most important terms related to capacity:

- Component,

- Capacity,

- Capacity plan,

- Capacity report,

- Capacity management information system (CMIS),

- Performance, and

- Capacity managers.

Component

A component is a fundamental structure of a particular service, an essential part of a service.

For example, the database is the component of an app or a server.

Since components are so significant, they have to be purchased, built, maintained, and monitored.

Capacity

According to the CIPS Institute, capacity represents the available resources that can be leveraged to meet a certain level of demand.

So, for instance, in a hotel, capacity would be the number of rooms, the availability of staff, and the hours during which hotel employees are working.

In a restaurant, capacity would be the number of tables and chairs available, the availability of restaurant staff, and the opening times.

Capacity plan

A capacity plan covers different scenarios for anticipated business demands.

Thanks to capacity plans, companies can make the best decisions on how to provide their customers with quality services while keeping prices cost-effective.

Capacity report

A capacity report is a document that contains data about service and resource usage and performance.

Keeping an eye on capacity reports helps managers make decisions about individual components.

Capacity management information system

The capacity management information system (CMIS) is the virtual repository that gathers all the data about capacity in one place.

Performance

Performance is a metric that shows how quickly a system is able to respond to requests.

For instance, how quickly an app can process data.

Capacity managers

In addition to these terms, we should also mention capacity managers. Capacity managers oversee the entire capacity management process.

They make recommendations regarding resources and their re-allocation. Also, capacity managers make plans for short, medium, and long-term business needs.

The process of capacity management

The process of managing capacity covers the matter of demand and supply of resources.

Demand means the number of products, items, or services that clients or customers are willing to purchase at a particular price.

Supply refers to the number of products, items, or services that companies can provide for their customers or clients, at a particular price.

Speaking of resources, capacity management covers resources like:

- Human capital,

- Hardware,

- Networking equipment,

- Peripherals, and

- Software.

When it comes to human capital, organizations have to figure out whether they have enough workforce. Companies may find the following questions useful:

- Do we have enough employees to cover all our projects?

- Do we have enough projects to provide our employees with a workload?

Learn more: What is workforce management and how it works? | Top 16 software for managing workforce

Additionally, leaders need to think about their team in order to equally delegate workload. Therefore, to schedule projects and employees properly, leaders have to answer these questions:

- Who is busy and who can handle more tasks?

- Who is overworked?

- When will particular members be available to start working on a new project?

Regardless of the type of business they operate in, companies must be flexible and adaptable to meet expectations from clients or customers. So, implementing an improved capacity management system may include actions such as:

- Working overtime,

- Outsourcing company operations,

- Buying additional equipment, and

- Selling commercial property.

Examples of capacity management

In order to understand capacity management, we need to consider its two vital elements — supply and demand.

Let's look at these examples of supply on a daily, weekly, and monthly basis:

- A fast-food truck that can make 700 sandwiches per day.

- A call center that can conduct 1,200 calls per week.

- A toy factory that can put together 5,000 toys per month.

If there's a demand for 700 sandwiches per day, and this demand is always met, this fast-food company is working well — so this is an example of efficient capacity management. That means this company has enough employees to cover daily demands during their working hours. Moreover, this fast-food truck likely has sufficient equipment, hardware, software, and peripherals that employees can use when working.

Now, what if demands change? What if there's a greater demand for sandwiches daily (1,000 per day)?

In that case, the fast-food company needs to adapt its capacity management.

When it comes to this fast-food company, they can decide to outsource some parts of its operations, like baking sandwich buns. Instead of doing this by themselves, the fast-food company can hire a bakery. Thus, employees working in this fast-food business will save valuable time (since they won't bake anymore) and use it to make 1,000 sandwiches per day.

On the other hand, if the call center has to enhance its capacity management in order to conduct 1,500 calls per week (instead of previously-mentioned 1,200), they may opt for working overtime.

Furthermore, let's say that the toy factory has to produce 7,000 toys per month (instead of the usual 5,000), before the Christmas season. To level up their capacity management, the toy factory can choose to buy additional equipment or machinery.

What are the main elements of capacity management?

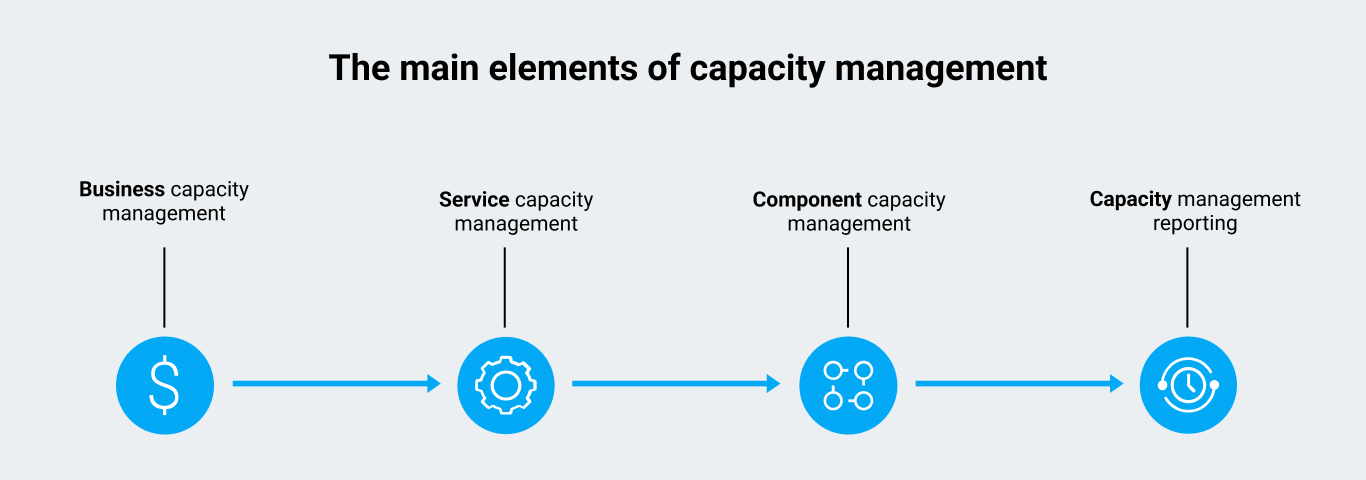

There are four main elements of capacity management:

- Business capacity management

- Service capacity management

- Component capacity management

- Capacity management reporting

Let's dive deeper into each element.

Business capacity management

Business capacity management covers business needs and plans regarding IT services and infrastructure. This sub-process includes reviewing all the data about demands. That way, companies make sure that the IT service will be completed correctly.

Service capacity management

Service capacity management involves predicting, managing, and controlling the performance of the operational IT services, from the beginning of the project to its end.

This sub-process reviews the resources, working patterns of the IT service, as well as the lows and peaks of this service.

Component capacity management

Component capacity management covers handling and overseeing the performance, usage, and capacity of each IT component.

Since hardware components usually have a specific capacity, these capacities need to be measured. That way, component capacity management ensures that there aren't any performance-related problems.

Capacity management reporting

Capacity management reporting provides other service management processes and IT management with important data about service capacity, service usage, and service performance. The data is then presented in the service capacity report

What are the objectives of capacity management?

The main objectives of capacity management are:

- Identifying the demands of IT capacity. That way, companies are able to meet current and future workload demands.

- Developing and maintaining a capacity plan.

- Giving guidance and advice regarding capacity and performance.

- Ensuring that service performance achievements are aligned with their targets.

- Assisting when issues arise by providing diagnosis and coming up with solutions to these problems.

- Improving performance by taking proactive measures.

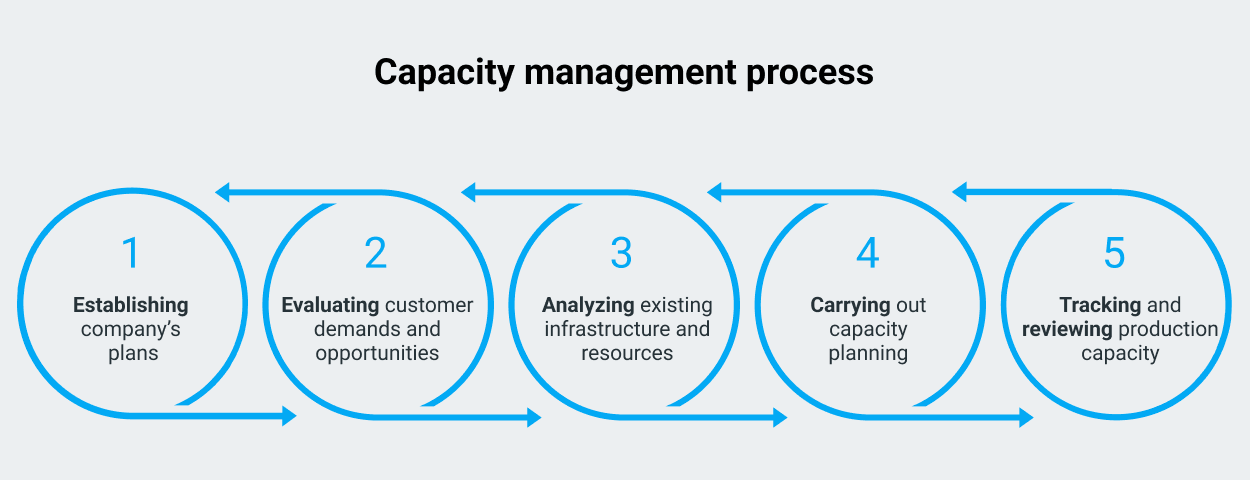

Capacity management process

The capacity management process includes the following steps:

- Establishing company's plans

- Evaluating customer demands and opportunities

- Analyzing the output of current infrastructure and resources

- Carrying out capacity planning

- Tracking and reviewing production capacity

Now, let's see what each of these processes cover.

Step 1: Establishing company's plans

The first step of the capacity management process is quite straightforward. Businesses need to know the exact demand for production in the months ahead. That's the most efficient way to manage capacity.

When having a clearer understanding of the company's plans, the company management will be able to decide whether to hire more employees or if machine maintenance is needed.

Step 2: Evaluating customer demands and opportunities

The next step in the capacity management process is understanding the market trends throughout the year. Thus, businesses will be able to forecast customer demands more precisely.

For instance, market trends can cover some crucial events, such as the Super Bowl, or seasonal trends, like Christmas or Easter season.

Let's use the aforementioned example of a toy factory. The Christmas season is approaching, and the company has to meet the demand of its customers.

Instead of putting together 5,000 toys per month, they'll have to increase the number of products to a total of 7,000 toys per month. So, during October and November, this is the customer demand of the toy factory.

Step 3: Analyzing the output of current infrastructure and resources

Now that companies are aware of the future demands, company management needs to follow the third step — analyzing the output of current infrastructure and resources.

In other words, will companies be able to meet customer demand with their existing resources and infrastructure?

If not, businesses will have to lease or buy new machinery or equipment. Furthermore, companies may have to hire new employees to operate this equipment or perform other tasks.

In the case of the toy factory, the company may decide to buy additional machinery. Moreover, the company will need to figure out whether they have enough toy designers to come up with ideas for new toys.

To do so, managers should first analyze whether their current toy designers are available for this vital Christmas project, or whether they have to hire more designers. Once they gather the team, leaders have to create project schedules.

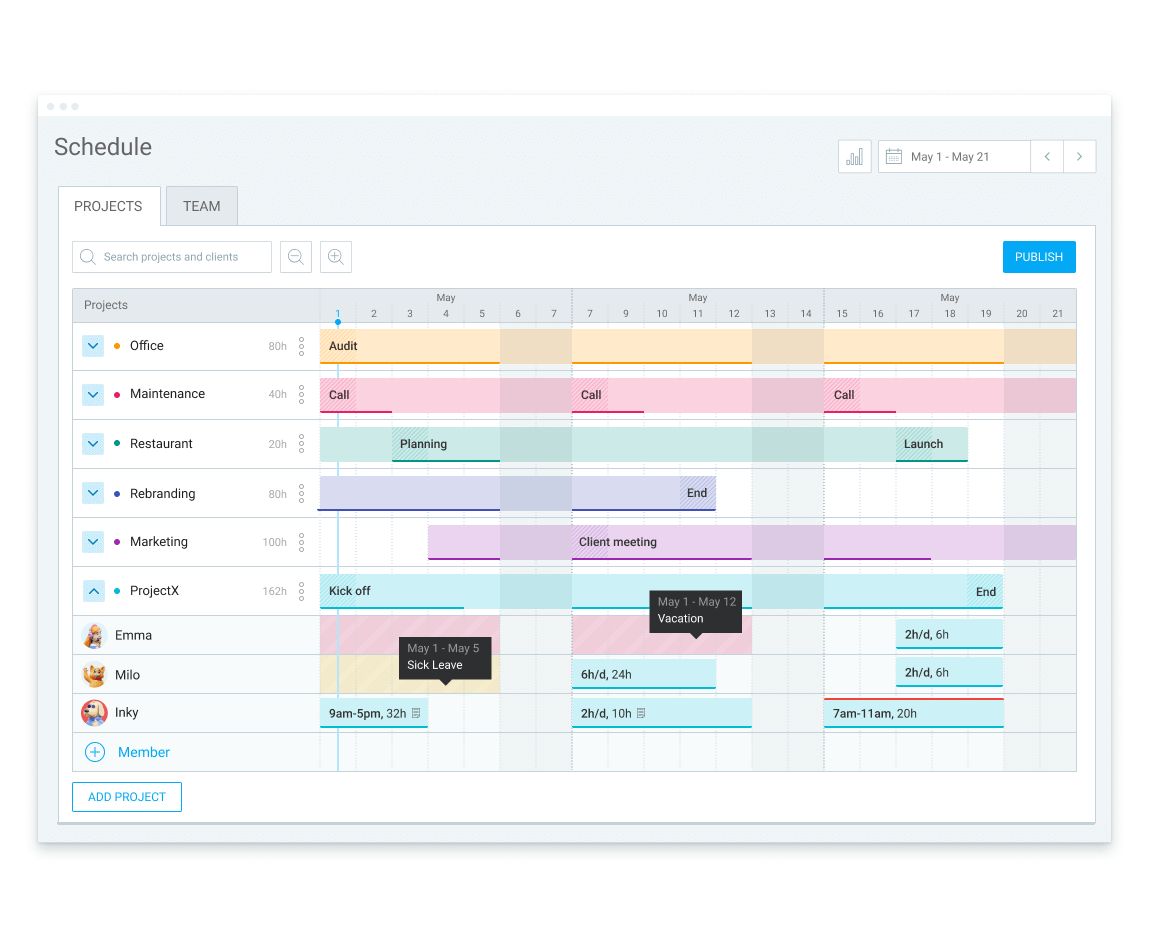

Since Clockify can also be used as a project scheduling tool, managers can use the scheduling feature to plan projects on a timeline.

As you can see from the screenshot above, you can add different project stages to the timeline, like a project kick-off or client meetings. You can also add or remove team members, as well as include milestones to remember crucial stages of the project.

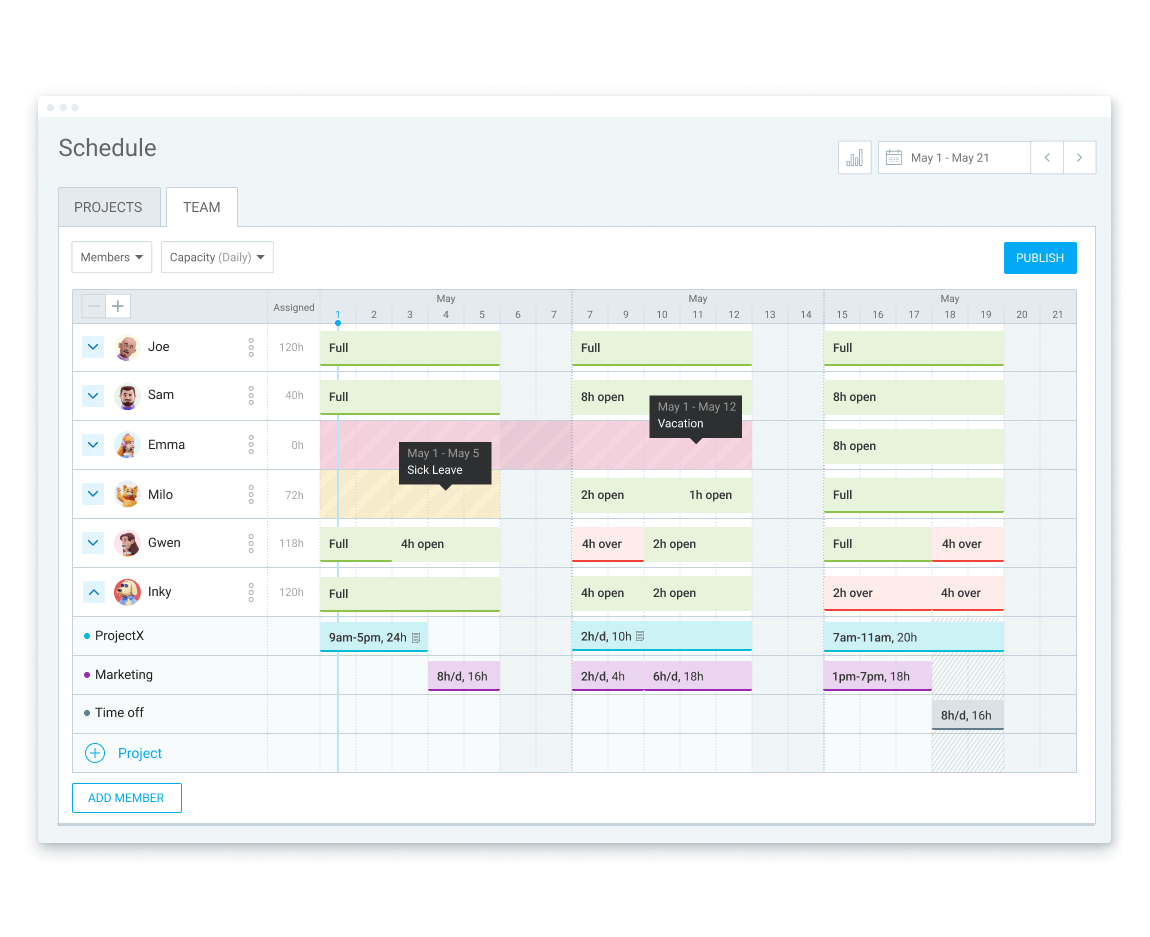

Let's recall our toy factory example. Higher customer demands during the Christmas season imply more work for the entire team of toy designers. So, managers can use the scheduling feature to review employees' schedules and delegate the workload. As we can see in the screenshot above, schedules can be:

- Full: employees' workload is at their full capacity.

- Open: employees have time for additional work.

- Over: employees' workload is over their capacity.

This way, managers will figure out whether they have enough resources for the current project.

Step 4: Carrying out capacity planning regarding the decision

Once companies complete the third step — decide whether they have enough infrastructure and resources to meet demands, the next logical step is implementation.

If businesses decide to purchase new equipment or machinery, then this step is buying new machinery and installing them.

Once this part is completed, companies will be able to match the demand and supply.

Step 5: Tracking and reviewing production capacity

The final step of the capacity management process is making sure that the capacity plan works well and suits the company's needs. Therefore, businesses need to constantly track and review the process related to capacity.

Why is capacity management important?

Here are the most crucial benefits of capacity management:

- It provides enhanced performance and availability of IT services.

- It helps companies figure out what activities are long-term and strategic, and what activities are daily operations assignments.

- It ensures fewer issues and incidents when it comes to capacity and performance.

- It ensures that necessary capacity and performance are profitable.

- It advances the reliability of the budget related to capacity.

What are the different challenges of capacity management?

We talked about the importance of capacity management in the workspace. Now, managing capacity isn't always an easy task.

According to the Forbes article, these are the most common challenges related to capacity management:

- The data challenge

- The challenge of complexity

- The communication challenge

Let's explore each one in more detail.

The data challenge

Capacity planners handle a lot of information that they usually enter in manual spreadsheets. To have a proper capacity management process, the data inputs have to be accurate and written in the right format (the same units of measure). As you can imagine, making mistakes by writing down incorrect information can affect the entire process of managing capacity.

Once capacity planners add the data, they also need to include details regarding demand and supply, then use a formula that helps them see information about available capacity.

The challenge of complexity

This challenge is in line with the previous one.

Since capacity planners work with formulas and calculations, there will likely be some mistakes along the way. Just like we mentioned earlier, adding wrong data to the spreadsheets can harm the entire process.

In addition, things can get even more complicated because capacity management usually involves multiple levels in manufacturing. Completing each of these levels takes time and requires additional data. Therefore, getting a final capacity plan involves so many employees, which increases the risk that someone makes (an unintentional) mistake — which brings us to the next challenge.

The communication challenge

To prevent making any mistakes when entering data, it's important that all employees involved in capacity management regularly exchange information.

Thus, keeping communication clear and transparent is crucial for the success of capacity management. When there aren't any communication gaps between employees, it's more likely that the process of managing capacity will be done accurately.

Now that we've talked about the challenges that may occur during this process, let's explore the most effective strategies for overcoming issues.

Capacity management strategies

The most practical capacity management strategies you can use are:

- Lag strategy

- Lead strategy

- Dynamic strategy

- Match strategy

We'll further explain how you can make the most of each strategy.

Lag strategy

The first step that capacity managers take in this strategy is determining the capacity.

Then, capacity managers wait for an increase in demand. That's the sign that managers should enhance production capabilities to meet market needs.

Although quite useful, this strategy has one key drawback. If market demands happen too quickly, companies might miss their opportunities to sell more products/services. That's because enhancing production capabilities takes time.

Lead strategy

Compared to the Lag strategy, the Lead strategy is riskier and more aggressive.

When using Lead strategy, capacity managers make decisions to enhance the capacity even though there's no actual demand on a market. Managers assume that there will be demands and hope that the enhanced capacity will be sufficient.

Now, in what cases do companies conduct this strategy?

It usually happens when companies expand. In addition, companies working in industries with frequent sales demands usually opt for a Lead strategy.

The main issue with this strategy is that it's risky.

If demands don't increase, then the inventory storage costs can only go higher, which is yet another problem for companies. Consequently, when there's more capacity in inventory storage than needed, there's a risk of inventory wastage.

Dynamic strategy

This strategy is much safer than the previous one.

In Dynamic strategy, capacity managers evaluate the actual demands on the market and sales forecast data.

Then, according to the current demands, capacity managers modify production, so it fits demands.

Dynamic strategy is a very safe way to properly take care of capacity management because managers make decisions following the forecasted data. Furthermore, there's less chance for wastage of inventory, too.

Match strategy

This strategy is a mixture of Lead and Lag strategies.

Here's how the Match strategy works: when it's evident that demands will increase, companies enhance their production in small amounts.

Just like the Dynamic strategy, this one is a pretty safe solution as well.

If demands level up quickly, companies can boost their sales a bit, since they've already increased production in small amounts.

On the other hand, if demands don't go up, companies won't have any losses because they've only enhanced production for a bit.

The key downside of this strategy is that businesses will never experience a peak in demand. Additionally, companies won't be able to escape sudden recession on a market.

Conclusion

Capacity management is the best method companies can use to maximize their production output. Moreover, when managing their capacity properly, businesses will have a clearer picture of how much they can achieve, produce, or sell within a specific period.

One of the most crucial benefits of capacity management is that it ensures fewer problems and incidents related to capacity and performance. Furthermore, this process is beneficial because it makes sure that capacity and performance are profitable.

Even though companies may experience some challenges when managing capacity, there are great ways to overcome these problems. In this article, we covered four vital capacity management strategies, and explained each of them in more detail.

So, if your business has some issues related to capacity, we hope that you'll find some of these strategies helpful.